Published on the 01/04/2025 | Written by Heather Wright

The Waikato Uni project decarbonising industry through tech…

Professor Michael Walmsley has a big goal: He wants to see New Zealand’s meat and dairy sector be net zero across all 300+ factories, cost effectively – ‘in other words, they are thriving, successful and making money’ – and his team are harnessing digital twins in their push to do so.

Walmsley, Waikato University School of Engineering Teaching and Research professor, is spearheading the University’s $12.5 million Ahuora Digital Twin project, with plans to commercialise the work in the next couple of years.

“Just more science is not needed. We need integration of what we know to solve the problem.”

The project focuses on the smart integration of technology to help to decarbonise New Zealand’s industry process heat sector, which contributes 28 percent of New Zealand’s energy emissions. Steam is used to dry milk powder and do certain functions in the meat factories and it’s that energy the Waikato University team are targeting.

But moving factories away from natural gas and coal isn’t cheap – and there’s no single silver bullet technology to make the move. Instead, a range of technologies need to be integrated at industrial sites, providing a unified energy system.

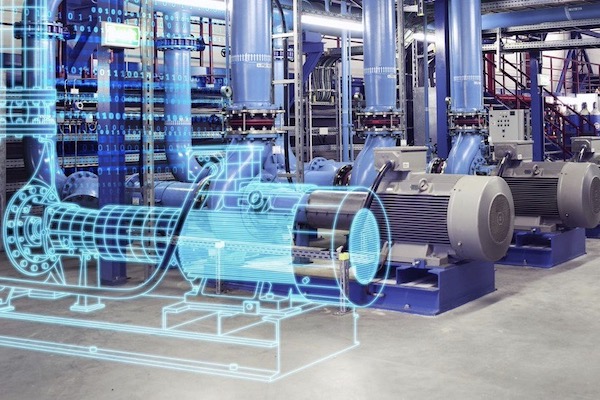

The Ahuora adaptive digital twin energy technology platform will provide a virtual model of a physical environment, enabling businesses to model in real time how energy is being supplied and consumed, and the impact of any changes. Real-time data will be shared between the physical and virtual domains. As an adaptive system, the digital twin can respond to changing circumstances and ‘learn’ from previous experience to better support real-time decision making and longer-term strategic platforms.

“Imagine if, in a factory, you had something running alongside the factory and if a heat exchanger – something that transfers heat back and forth to the process – was starting to not perform well because it was getting dirty. The digital twin might warn the company or operators the equipment needs to be cleaned or repairs are needed,” Walmsley told iStart.

“It becomes a device they can make decisions off.”

The project is developing software that can look at processes from the very small to large scale such as processor sites at a regional level, along with behaviours and model the behaviour of the system and the likeness.

The digital twin can be connected with other inputs, such as nearby solar farms.

Walmsley is clear that New Zealand needs to be putting more focus into funding problem solving for business, rather than simply research for the sake of greater knowledge.

“At universities, we have all these fancy research tools we are developing and using, but there is a big gap between what we are doing at the universities and what actually happens in industry.”

Ahuora has been working with industry partners including the likes of Fonterra, ANZCO, Golden Bay Cement, Waitaki Biosciences and a number of energy providers, and service and equipment providers including Tetra Pak, TemperZone and Aurecon.

“We have talked a lot with industry partners to identify what the gaps are – the things they wish they could do, but can’t because they don’t have enough information or the tools aren’t available.

“Generally, industry and the service providers are basically followers. They are not that interested in disruptive solutions because it is risky. That’s why it pays to have a researcher involved because we can investigate some of these potentially disruptive technologies, test them out and lower the risk for these parties.”

A number of potential solutions to a range of problems have been developed, including development of ways of analysing data beyond the normal factory ranges and using AI and neural networks for neural network modelling for a pulp and paper factory.

Once the tools are proven, the team looks at how it can be applied as a more generalised method, enabling it to work for other sites or sectors, and Ahuroa’s software engineers code it up into a software tool that integrates into the digital twin platform.

“So you can have the simulation and then use tools – high level mathematical and in some cases AI and machine learning tools – to make sense of the data better,” Walmsley says.

“Ultimately what we are trying to do is use the digital twin and AI tools to help factories make operational and design decisions better.”

A beta version of the software was debuted to industry to trial in late March.

Walmsley says the platform has been developed to be ‘very intuitive – click, drag and attach things to make up process layouts very simply. And then there are the other tools you can bring in when you come to analysing.”

He says Tetra Pak, which designs and builds a large percentage of dairy factories in New Zealand, was developing a new plant, is ‘a big potential user of our tools’ and are ‘very interested’ in the project.

But he’s not just eyeing up the Kiwi market and says Australia offers huge potential for the initiative, as does the wider global market.

“There is a lot of food production in Australia and there is not a lot of expertise in energy system integration. We started in energy system integration almost 20 years ago and we probably have the strongest research group in that process integration area now.

“Even globally, we think we can have an impact, especially in the food sector.”

And it’s not just about industry: While the Ahuora digital twin is currently focused on industrial tools, Walmsley says it will be expanded to the community and then regional level.

While companies such as Transpower and WEL Networks already model their grids, he says ‘ultimately we see this being able to be connected in more detail at the community and industrial level’.

That includes looking at the impacts of solar or wind farms on electricity costs, and the impact of increased demand on the electricity network as industry moves to electric, and consumers also ramp up their electricity demands.

“Having a system that provides cheap electricity should be one of our main focuses. I agree with Xero founder Rod Drury who once said rather than decarbonise, let’s just say the cheapest renewable electricity. That’s a good goal and decarbonising will happen.”

The ultimate goal is to commercialise Ahuora’s work, something Walmsley hopes to see done before the seven-year project winds up in June 2027. Waikato University received $12.5 million in government funding for Ahuora, which kicked off in 2020.

Whether the commercialisation will result in a SaaS platform being offered, or a consulting business working with industry to use the tool, is yet to be decided, though Walmsley says initially at least, the University’s students will be working with companies to demonstrate its usefulness.

“The industry are interested in how is this useful for them. In order to do that we need a problem that they are wrestling with. Then we can work together, build a simulation of that portion of the factory you want to improve or do something with, and then apply some of these tools to help identify what is the critical parameters controlling the performance of your process, for example and the impacts of changes.

“It’s a bit like Steve Jobs and how he used to whet people’s appetite for what the new iPhone could do – we’re trying to whet industry’s appetite.”

He says government is pumping too much money into the ‘cutting edge science fundamental level’ through MBIE programs such as Endeavour and Marsden, while EECA is offering money for pilot and first full-scale schemes.

“And industry has to spend a lot of money whenever they make changes to their factories or build a new factory.

“One of the things we’re getting wrong is that spend.”

European funding models are more focused on higher up the tech readiness level – work to prove feasibility, develop and demonstrate the technology – rather than simply research.

“If you want to see more impact in industry, you have to be prepared to fund this less, and put more money into the higher technology readiness levels.

“Just more science is not needed. We need integration of what we know to solve the problem.”